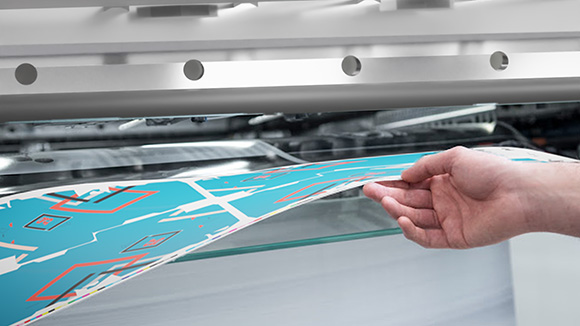

Prepress

Once the packaging designs have been agreed with the customer, they are prepared for printing by our specialists. If any elements or parts of the packaging design must be expanded or changed, we make all the necessary correctional changes and send proof print for client approval.

Printing plates are made using CTP (Computer-to-Plate) digital offset plate production equipment.

Offset printing

We print on six-color sheet-fed offset presses with two coating sections (UV and dispersion varnish). For printing, we use materials that are suitable for food packaging.

UV coating

The two coating sections on our printing machines allow us to achieve special effects through coating:

- UV coating + dispersion varnish

- Dispersion varnish + dispersion varnish.

We can coat with glossy or matte varnish, perform partial or full coating with dispersion or UV coatinges. We can create a "Soft Touch" effect - a surface like peach skin. Or achieve a "Drip off" - a textured surface - effect.

FLAT AND EMBOSSED (3D) HOT FOIL STAMPING

With our automatic die-cutting and foil stamping machine, we carry out standard and embossed (3D) foil stamping work. We use various foils, including metallic and holographic ones.

EMBOSSED IMPRINT

We achieve embossed imprint (debossed and embossed) using the cold embossing method.

BRAILLE SCRIPT

Using the "Vega Polaris" folding-gluing machine, we imprint Braille script on pharmaceutical product packaging according to the requirements of European Directive 2004/27/EC.

Cutting

With our automatic cutting machines, we cut the most complex boxes according to your design and form folding and perforation lines.

WINDOW PATCHING

We use a window patching machine to glue various shapes and sizes of transparent windows onto packaging boxes.

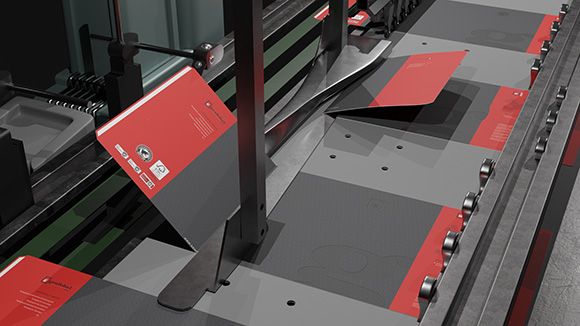

Folding and gluing

Our folding-gluing machine enables us to produce complex structure boxes with up to 8 gluing points.

Additionally, we fold over the folding lines of boxes intended for packaging machines.

Tray forming

With our cardboard box forming machine, we can produce boxes for meat products, snacks, take- out food containers, and more.

We can form not only boxes of various sizes but also corrugated cardboard up to 1.5 mm thick.